Direct Drive vs. Belt Drive vs. Gear Drive Pressure Washers: Which One Lasts for Your Workload?

01/ 16/ 2026 by Arwin

Every pressure washer can clean a driveway. The real question is: how long will it keep doing it once the jobs get real?

The difference between machines doesn’t always show up on the first job or even in the first month. It becomes glaringly obvious after long workdays, rising pump temperatures, frequent transport, and back-to-back cleaning contracts. This is the moment where a commercial or professional pressure washer is expected to keep humming or start failing. At this stage, the drive system stops being a spec on a product page and starts becoming either a liability or a long-term asset.

Why do so many contractors replace their equipment sooner than expected? Usually, it isn't bad luck. It's a mismatch between the drive system and the actual workload.

At Spraywell, we know that professional cleaning is not a "standardized industry". Different jobs require different mechanical advantages. This is why we engineered the Stealth line of pressure washers. We did not just stick to one type of machine. We developed a range of direct drive, belt drive, and gear drive pressure washers intentionally, so professionals can choose the system that suits their specific work style. Here is how to break down the drive systems based on how you actually work.

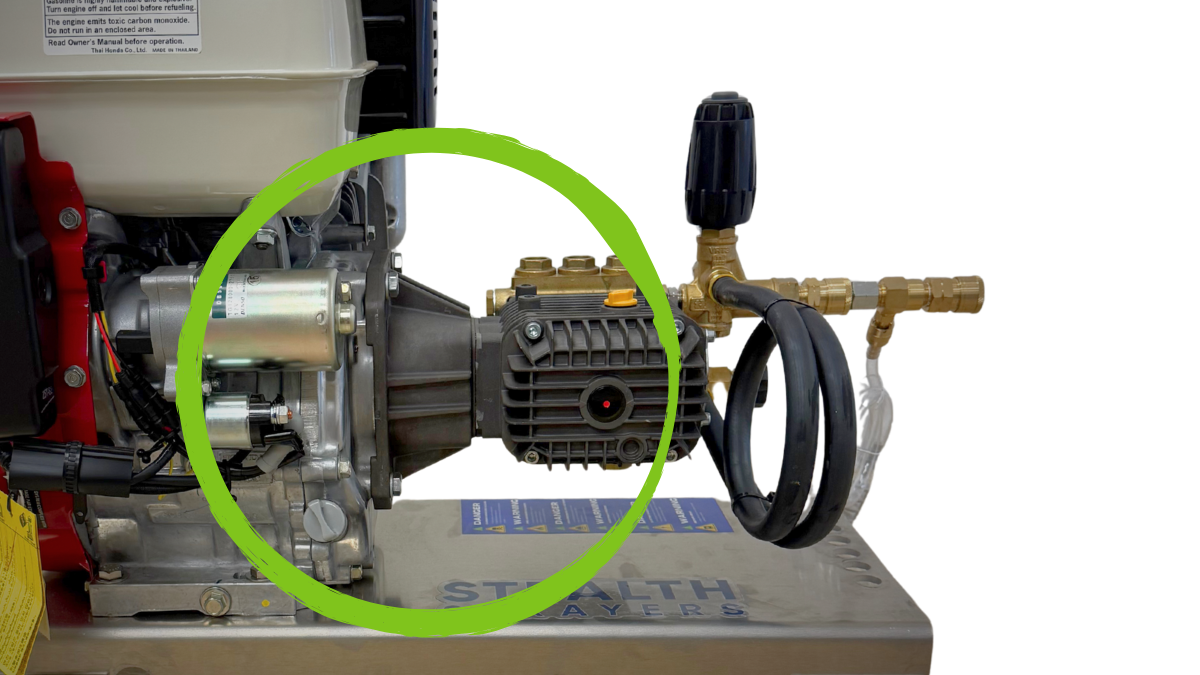

Direct Drive: Compact, Simple, and Efficient

Direct drive pressure washers connect the engine or motor directly to the pump. Because the pump spins at the same high RPM as the engine, this design minimizes power loss and keeps the footprint small.

Pros:

- Minimal Maintenance: Fewer moving parts mean fewer things to grease, tighten, or replace.

- Portability: The compact, lightweight design is ideal for tight trucks or frequent loading and unloading.

- Efficiency: High power transfer for residential and light commercial pressure washing tasks.

- Affordability: Lower upfront cost makes it a more economical option and excellent entry point for new businesses.

Cons:

- Heat Sensitivity: Because the pump is bolted to the engine, heat transfers quickly, which can be an issue during all-day operation.

- High Wear Points: The keyway and key that connect the shafts can become high-wear points over time. These are often more expensive and labor-intensive to fix than a simple belt replacement.

- Vibration: Higher RPMs mean more wear and tear on the pump seals over thousands of hours.

- Noise: Operating at higher RPMs typically results in a noisier machine compared to reduced-speed systems.

- Trigger Management: Because there is no clutch system, the pump is always moving if the engine is running. If you stay off the trigger for too long, the recirculating water heats up rapidly and can damage the pump.

- Water Source Limitations: Direct drive pumps generally cannot pull water from a static tank. They usually require the active pressure of a garden hose or a 12-volt feed pump to operate correctly.

Choose this if... your work involves short, intermittent pressure washing jobs with frequent stops and starts. If you specialize in residential driveways, patios, fences, or vehicle detailing, a Stealth Direct Drive unit delivers the PSI and GPM you need in a package that won’t break your back—or your budget.

Featured Stealth RogueJet Series Direct Drive Models:

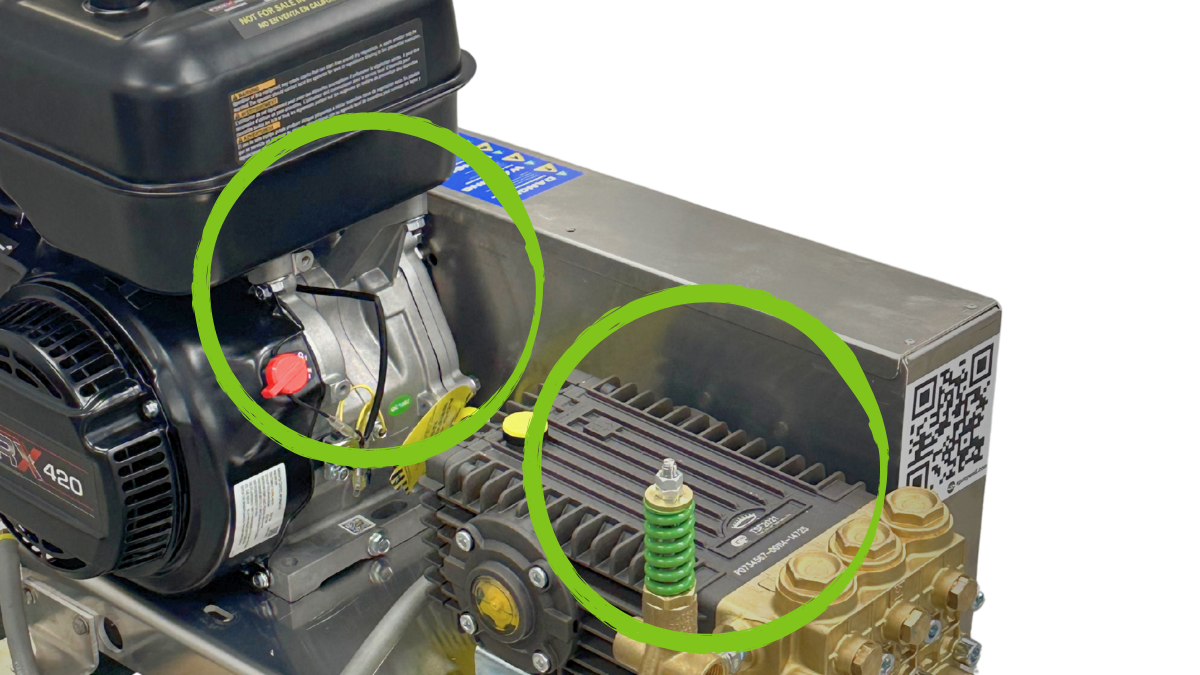

Belt Drive: Smooth, Flexible, and Durable

Belt drive pressure washers use a pulley system to transfer power. This allows the pump to run at a much lower RPM (usually about half the speed of the engine). By separating the pump from the engine's heat and vibration, you significantly extend the life of the internal components.

Pros:

- Cooler Operation: The physical gap between the engine and pump prevents heat soak, allowing for longer run times.

- Component Safety: If a pump or motor seizes up, the belt acts as a safety. It will usually snap or slip, preventing the total destruction of the other half of the machine.

- Easier Priming: Lower RPM pressure washing pumps are much easier to prime, which is a major advantage when dealing with variable water supply situations.

- Longevity: Lower RPMs mean less friction and a much longer lifespan for pump seals and valves.

- Quiet & Smooth Performance: Belt systems absorb vibration, leading to quieter operation.

Cons:

- Size: These units are naturally larger and heavier than direct drive models.

- Maintenance: Belts require periodic tension adjustments and eventual replacement.

Choose this if... you are a professional contractor tackling larger commercial properties or repeated daily use. If your machine stays running for hours at a time or you need to draw from a water tank, Stealth’s Belt Drive pressure washers strike the perfect balance between heavy-duty durability and mechanical efficiency.

Featured Stealth Operator & Spectre Series Belt Drive Models:

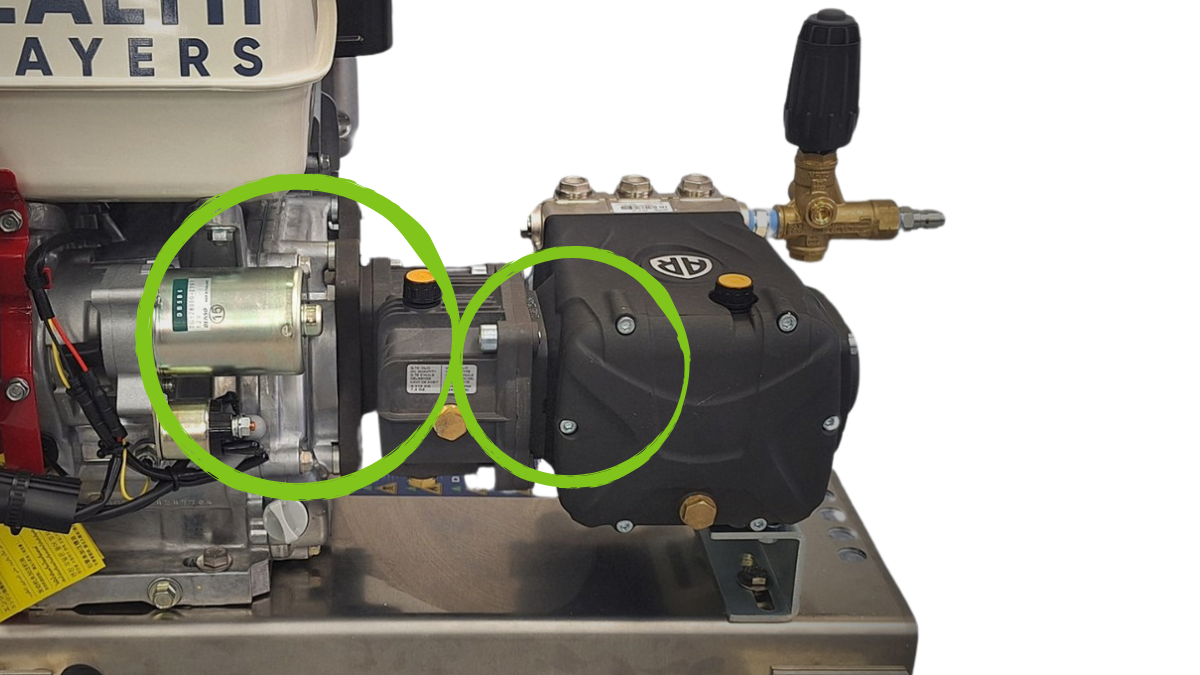

Gear Drive: Heavy-Duty Power for Maximum Workloads

Gear drive systems are the heavy hitters of the industry. They use a hardened gear reduction box to slow the pump down (like a belt drive) but keep the compact footprint of a direct drive. These are built for environments where downtime is not an option and the workload is relentless.

Pros:

- Extreme Durability & Maximum Power Transfer: Hardened gears provide the most reliable and consistent power transfer available today.

- Compact Strength: You get the low-RPM longevity of a belt drive without the massive, wide frame.

- Low Maintenance: No belts to slip or snap; just simple oil changes for the gear box.

Cons:

- Investment: These tend to be slightly more expensive units due to the precision engineering of the gear box.

- Weight: While compact, the gear box adds significant weight to the engine-pump assembly.

Choose this if... your work involves all-day industrial cleaning, fleet washing, or high-frequency municipal contracts. Stealth’s Gear Drive units are designed for the contractor who pushes their equipment to the absolute limit and needs a machine that won't quit until the job is done.

Featured Stealth Operator Gear Drive Models:

-

Stealth 5.5 GPM 3000 PSI Pull Start Pressure Washer (Honda | CRX)

- Stealth 5.5 GPM 3000 PSI Electric Start Pressure Washer (Honda | CRX)

Making the Right Choice for Your Business

Choosing a drive system isn't about which machine is "better". It's about matching the tool to the task. Selecting the wrong drive type for your pressure washer can lead to premature pump failure, high maintenance costs, and lost revenue. Choosing the right one makes your workday more efficient and your business more profitable.

The Takeaway: Don’t shop for a pressure washer based on the GPM & PSI sticker alone. Consider your daily runtime, how often you transport the unit, and the intensity of your average job.

Ready to upgrade your fleet?

Browse our full lineup of Stealth Gas-Powered Pressure Washers today to find the direct, belt, or gear drive system built to handle the real demands of your work.